What is the function of installing probe on CNC lathe? Time is money, save artificial knife, artificial workpiece positioning and detection is to save money. The addition of the probe system can shorten most of the cost of manual and offline detection and manual assistance time, and reduce or even eliminate the waste caused by human factors.

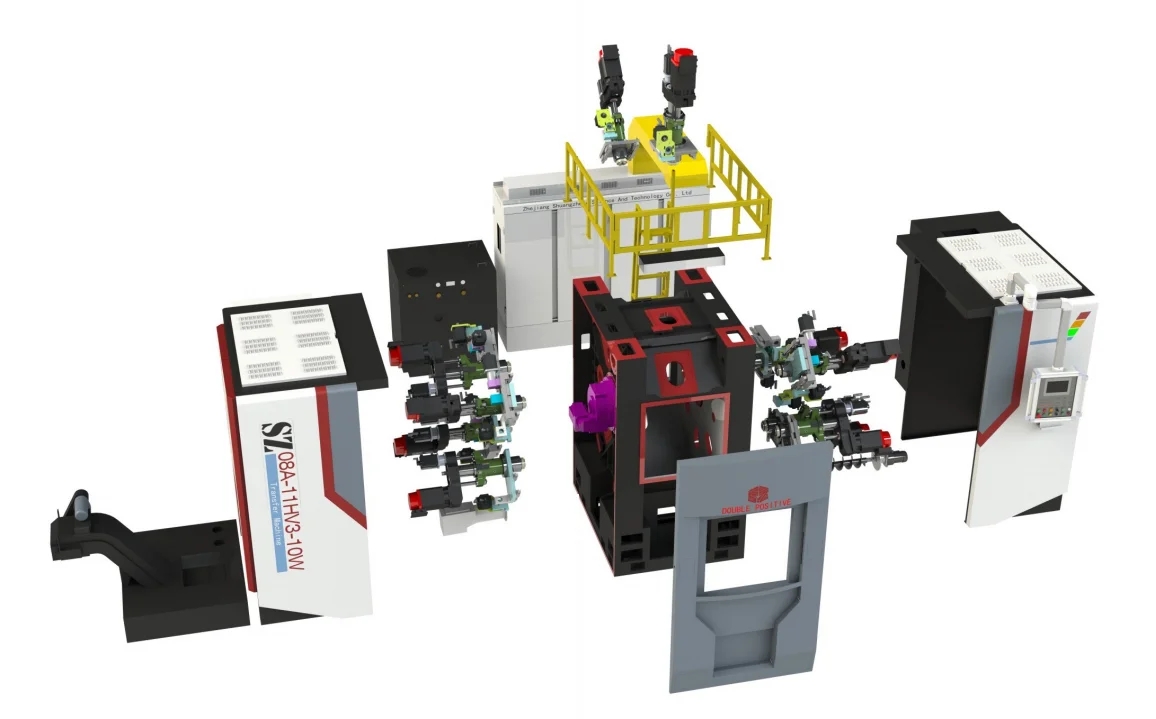

Will the expensive CNC lathe sit idle for a few hours when the first piece is tested offline? When measuring manually, moving the workpiece to a coordinate measuring machine or other off-line detection method is very time consuming. The machine tool probe can quickly complete the in-machine detection of the workpiece and automatically set the offset compensation value, improve the machining accuracy and avoid repeated clamping positioning. Use the probe to change the production method, save a lot of auxiliary time, reduce the scrap rate! Disc Type Special Machine The DISC type special machine installation probe is easy to use, and small batch processing can be faster.

CNC lathes are equipped with measuring heads to improve workpiece quality and productivity. The easy installation of the probe allows it to be fully installed on the factory's existing CNC lathes. The measurement package uses easy-to-program macros to control workpiece alignment, tool alignment and measurement process. These standard measurement programs are easy to plug into the workpiece machining program and can be automatically invoked by standard CNC lathe codes.

1. Reduce the load inertia ratio

The load inertia ratio is generally set to about 70% of the parameters shown when the vibration occurs. If the fault cannot be eliminated, you should not continue to reduce the parameter value.

2. Add Proportional Calculus (PID)

Proportional calculus is a kind of multifunctional controller, which can not only obtain the current and voltage signals in proportion, but also adjust the output signal lag to lead. Oscillatory failures are sometimes caused by lagging output currents and voltages. PID can be used to adjust the output current and voltage phase.

3. Use the high-frequency suppression function

The above discussion is about the optimization method of low-frequency oscillation parameters. Sometimes the feedback signal of the NUMERICAL control system contains high-frequency harmonics due to some mechanical oscillation reasons, which makes the output torque unstable and thus produces vibration. For such high frequency oscillations, a first-order low-pass filter, the torque filter, can be added to the speed ring.

Disc Type Special Machine https://www.zjshuangzheng.com/Disc-Type-Special-Machine.html